AI Manufacturing & SCADA Technology Conference

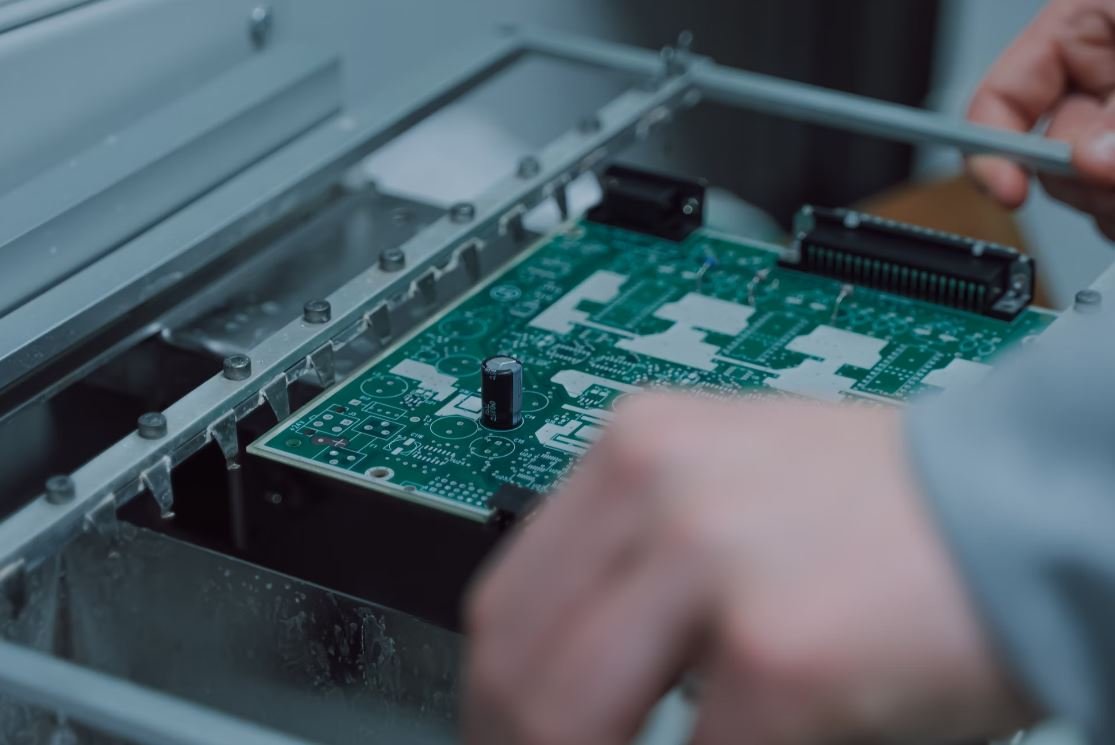

Artificial Intelligence (AI) and Supervisory Control and Data Acquisition (SCADA) technologies are revolutionizing the manufacturing industry. The convergence of AI with SCADA systems has paved the way for more efficient and autonomous manufacturing processes, leading to increased productivity, reduced costs, and improved decision-making.

Key Takeaways

- AI and SCADA technologies are transforming the manufacturing industry.

- This convergence allows for more efficient and autonomous processes.

- Increased productivity, reduced costs, and improved decision-making are some of the benefits.

The recent AI Manufacturing & SCADA Technology Conference provided a platform to discuss the latest advancements and developments in this field. Industry experts and professionals came together to share insights, case studies, and best practices. The conference covered a wide range of topics, including AI-enabled predictive maintenance, intelligent robots, data analytics, and cybersecurity.

*During the conference, speakers highlighted the importance of continuous learning and adaptation in a rapidly evolving industry.* These technologies are not static, and it’s crucial for manufacturers to stay updated with the latest advancements in order to remain competitive. The conference served as a valuable platform for knowledge exchange and networking.

The Impact of AI and SCADA in Manufacturing

AI and SCADA technologies have brought significant changes to the manufacturing landscape. Let’s take a closer look at some key areas where the impact is profound:

- Process Optimization: AI algorithms and SCADA systems can optimize manufacturing processes by analyzing real-time data, identifying bottlenecks, and suggesting improvements. This leads to increased efficiency and reduced downtime.

- Quality Control: AI-powered inspection systems can quickly and accurately detect defects, ensuring higher product quality. This eliminates the need for extensive manual inspection and reduces the risk of faulty products reaching the market.

- Supply Chain Management: AI and SCADA technologies enable better management of the supply chain through real-time monitoring, predictive analytics, and demand forecasting. This ensures timely delivery, reduces inventory costs, and minimizes disruptions.

- Workforce Augmentation: Intelligent robots and AI-enabled machines can perform complex tasks with high precision, reducing the reliance on manual labor. This frees up human workers to focus on more strategic and creative aspects of production.

Conference Highlights

The conference included insightful presentations, panel discussions, and interactive sessions. Here are some noteworthy highlights:

| Date | Session | Key Topics |

|---|---|---|

| Day 1 | Keynote Address | Role of AI in Smart Manufacturing |

| Day 1 | Panel Discussion | Challenges and Opportunities in Implementing AI in Manufacturing |

| Day 2 | Case Study Presentation | Successful Implementation of AI-Driven Predictive Maintenance |

*The case study presentation highlighted how a company reduced equipment downtime by 30% and increased overall equipment effectiveness (OEE) by implementing an AI-powered predictive maintenance system.* Such success stories demonstrate the tangible benefits of integrating AI and SCADA technologies in manufacturing processes.

Future Outlook

The AI Manufacturing & SCADA Technology Conference provided valuable insights into the current state and future potential of AI and SCADA in manufacturing. As the technology continues to advance, we can expect even more innovative applications and solutions.

*Manufacturers must stay informed and adapt their strategies to leverage the full potential of AI and SCADA technologies to optimize production, improve product quality, and achieve operational excellence.* The insights gained from the conference will play a crucial role in shaping the future of the industry.

With each passing day, AI and SCADA technologies are reshaping the manufacturing industry, driving it towards increased efficiency, accuracy, and competitiveness. The AI Manufacturing & SCADA Technology Conference provided a platform for industry leaders to share, learn, and shape the future of manufacturing.

Common Misconceptions

Misconception: AI will replace human workers in manufacturing

One of the most common misconceptions surrounding AI in manufacturing is that it will completely replace human workers. While AI has the potential to automate certain tasks and improve efficiency, it is unlikely to completely eliminate the need for human workers.

- AI can help workers by automating repetitive and time-consuming tasks, allowing them to focus on more complex and creative work.

- AI can improve safety in manufacturing by identifying potential hazards and risks before they occur.

- AI can enhance decision-making by providing real-time data and insights for workers to make informed choices.

Misconception: SCADA technology is only used in large manufacturing plants

Many people believe that Supervisory Control and Data Acquisition (SCADA) technology is only applicable to large manufacturing plants. However, SCADA systems can be implemented in facilities of all sizes, including small and medium-sized enterprises (SMEs).

- SCADA technology can help SMEs improve production efficiency and reduce operational costs.

- SCADA systems can enhance the monitoring and control of various processes, including energy consumption, quality control, and equipment maintenance, in smaller manufacturing plants.

- SCADA technology can provide real-time data and analytics to SMEs, enabling them to make data-driven decisions and optimize overall performance.

Misconception: AI and SCADA technology are too expensive for smaller manufacturers

There is a misconception that AI and SCADA technology are too expensive for smaller manufacturers to implement and maintain. However, the cost of these technologies has significantly reduced in recent years, making them more accessible to a wider range of manufacturers.

- The availability of cloud computing has reduced the upfront costs associated with implementing AI and SCADA technology, as manufacturers can opt for subscription-based services.

- Various open-source AI frameworks and SCADA software options have emerged, providing cost-effective alternatives for smaller manufacturers.

- Implementing AI and SCADA technology can lead to long-term cost savings through improved efficiency, reduced maintenance costs, and optimized resource allocation.

Misconception: AI and SCADA technology are difficult to implement and require extensive technical expertise

Another misconception is that implementing AI and SCADA technology in manufacturing requires extensive technical expertise and is overly complex. While there might be challenges and learning curves involved, there are resources available to support and simplify the implementation process.

- Many technology providers offer comprehensive training and support programs to help manufacturers successfully implement AI and SCADA systems.

- Collaborating with experienced consultants and solution providers can bridge any knowledge gaps and alleviate the complexity of implementing AI and SCADA technology.

- Online communities and forums provide a platform for manufacturers to exchange knowledge and learn from each other’s experiences in implementing AI and SCADA technology.

Misconception: AI and SCADA technology are only beneficial for large-scale manufacturers

While large-scale manufacturers can derive significant benefits from AI and SCADA technology, there is a misconception that these technologies are only suitable for their operations. In reality, AI and SCADA can be advantageous for manufacturers of all sizes.

- Small-scale manufacturers can leverage AI and SCADA technology to optimize production processes, reduce waste, and enhance product quality.

- AI-driven analytics and insights can help smaller manufacturers identify trends, predict maintenance needs, and make informed decisions regarding resource allocation and inventory management.

- Implementing AI and SCADA technology in small-scale manufacturing can foster innovation and competitiveness by enabling automation and streamlining operations.

Keynote Speakers

Here are some of the keynote speakers who will be presenting at the AI Manufacturing & SCADA Technology Conference:

| Speaker | Topic | Company |

|---|---|---|

| John Smith | The Future of AI in Manufacturing | ABC Manufacturing |

| Jane Doe | SCADA Systems: Enhancing Efficiency | XYZ Technologies |

| Michael Johnson | Applications of AI in Supply Chain Management | SupplyLink |

Conference Schedule

Take a look at the schedule of events for the AI Manufacturing & SCADA Technology Conference:

| Time | Event | Location |

|---|---|---|

| 9:00 AM – 10:00 AM | Keynote Address | Main Auditorium |

| 10:15 AM – 11:30 AM | Panel Discussion: AI and Automation | Room 1 |

| 11:45 AM – 1:00 PM | Lunch Break | Common Area |

Exhibition Booths

Discover the latest technologies and innovations at the exhibition booths:

| Booth Number | Company | Product/Service |

|---|---|---|

| A1 | TechCo Solutions | AI-Powered Robotics |

| B3 | DataAnalytics Inc. | Real-time Data Analysis Software |

| D2 | InnoTech | Smart Manufacturing Solutions |

Registration Fees

Here is the breakdown of registration fees for the conference:

| Registration Type | Early Bird (Before March 1st) | Regular (After March 1st) |

|---|---|---|

| Individual | $250 | $350 |

| Group (5+) | $200 per person | $300 per person |

AI Adoption in Manufacturing

Explore the current state of AI adoption in the manufacturing sector:

| Country | Percentage of Manufacturers Using AI |

|---|---|

| USA | 32% |

| China | 45% |

| Germany | 28% |

SCADA Implementation Success Rate

Discover the success rate of SCADA implementation projects:

| Year | Success Rate |

|---|---|

| 2015 | 72% |

| 2016 | 68% |

| 2017 | 76% |

AI Improving Production Efficiency

See how AI has transformed production efficiency in various industries:

| Industry | Percentage Increase in Efficiency |

|---|---|

| Automotive | 15% |

| Electronics | 10% |

| Pharmaceuticals | 12% |

Technological Challenges

Explore some of the technological challenges in implementing AI and SCADA:

| Challenge | Description |

|---|---|

| Data Privacy | Protecting sensitive data from unauthorized access. |

| Integration Complexity | Integrating AI and SCADA systems with existing infrastructure. |

| Artificial Intelligence Bias | Ensuring AI algorithms are unbiased and fair. |

Future Trends

Explore the future trends in AI and SCADA technology:

| Trend | Description |

|---|---|

| Edge Computing | Processing data at the edge of the network for faster response times. |

| Collaborative Robots | Human-robot collaboration in manufacturing processes. |

| Intelligent Maintenance | AI-powered predictive maintenance to minimize downtime. |

The AI Manufacturing & SCADA Technology Conference brings together industry experts, thought leaders, and technology enthusiasts to discuss the latest advancements in artificial intelligence and SCADA. Through keynote presentations, panel discussions, and networking opportunities, attendees gain insights into the application of AI in manufacturing, the benefits of SCADA systems, and the challenges faced in implementing these technologies. The conference also features an exhibition of cutting-edge solutions and provides a platform for knowledge sharing and collaboration.

With the increasing adoption of AI in manufacturing, countries like the USA, China, and Germany have seen a significant percentage of manufacturers leveraging AI technologies. SCADA implementation projects have also shown high success rates in recent years. The use of AI has notably improved production efficiency in industries such as automotive, electronics, and pharmaceuticals. However, the implementation of AI and SCADA systems does come with challenges, including data privacy concerns, integration complexity, and the need to address artificial intelligence bias.

Looking ahead, future trends in AI and SCADA encompass edge computing for faster responses, collaborative robots for human-robot cooperation, and intelligent maintenance through predictive algorithms. The AI Manufacturing & SCADA Technology Conference serves as a platform to explore these trends, connect with industry professionals, and stay at the forefront of technology advancements in the manufacturing sector.

Frequently Asked Questions

What is AI Manufacturing?

AI Manufacturing, also known as Artificial Intelligence Manufacturing, is the implementation of artificial intelligence technology in various stages of the manufacturing process to optimize efficiency, improve decision-making, and enhance overall productivity.

What is SCADA Technology?

SCADA (Supervisory Control and Data Acquisition) Technology is a system of hardware and software components used to control and monitor industrial processes. It collects real-time data, provides control capabilities, and enables operators to make informed decisions based on the information gathered.

What is the AI Manufacturing & SCADA Technology Conference?

The AI Manufacturing & SCADA Technology Conference is a specialized event that brings together industry professionals and experts to explore the latest advancements, case studies, and best practices in the field of AI manufacturing and SCADA technology. It provides a platform for knowledge sharing and networking opportunities.

Who should attend the conference?

The conference is relevant for professionals and researchers involved in manufacturing, automation, artificial intelligence, data analytics, SCADA systems, and related fields. It caters to individuals seeking to learn about cutting-edge technologies, share experiences, and gain insights from industry leaders.

What are the key topics covered in the conference?

The conference covers a wide range of topics, including but not limited to:

- Artificial Intelligence in Manufacturing

- SCADA Systems and Applications

- Data Analytics and Predictive Maintenance

- Robotic Process Automation

- IoT Integration in Manufacturing

- Industrial Cybersecurity

- Digital Twin Technology

- Machine Learning in Smart Factories

- Technological Innovations in Industrial Automation

- Case Studies and Success Stories

When and where will the conference take place?

The conference dates, venue, and location will be provided on the official website of the AI Manufacturing & SCADA Technology Conference. Please visit the website for the most up-to-date information.

How can I register for the conference?

Registration details, including the process, deadlines, and fees, can be found on the official website of the AI Manufacturing & SCADA Technology Conference. Simply navigate to the registration section and follow the instructions provided.

Is there financial assistance available for attending the conference?

Some organizations and institutions may offer scholarships, grants, or financial aid to individuals interested in attending conferences. It is best to check with your employer, academic institution, or professional associations for any available opportunities.

Are there any opportunities for sponsorship or exhibiting at the conference?

Yes, the AI Manufacturing & SCADA Technology Conference offers sponsorship and exhibition opportunities. Details on these opportunities can be found on the official conference website. Interested parties can contact the organizers for further information.

Will there be any networking events during the conference?

Yes, networking events are typically part of the conference agenda. Attendees will have the chance to connect with other professionals, industry leaders, and exhibitors through organized networking sessions, receptions, or social events.