Artificial Intelligence in Production

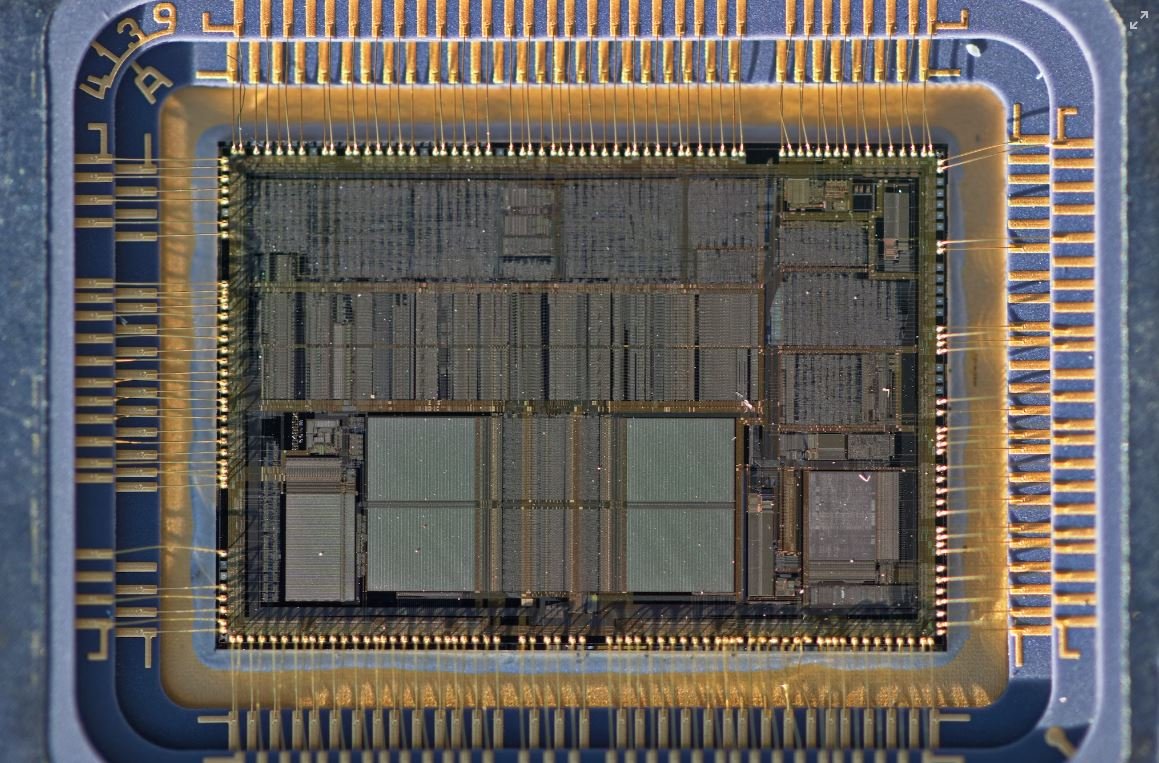

Artificial Intelligence (AI) has become an essential tool in various industries, and the field of production is no exception. AI technology is revolutionizing the way businesses manufacture and deliver products, leading to increased efficiency, cost savings, and improved quality control. In this article, we will explore how AI is being utilized in production, the benefits it brings, and the challenges it presents.

Key Takeaways

- AI technology is transforming production processes.

- It enables predictive maintenance and real-time monitoring.

- AI-powered machines can optimize production schedules.

- Automated quality control improves product consistency.

- Implementing AI requires significant investments in infrastructure and training.

*Artificial Intelligence enables predictive maintenance by using machine learning algorithms to analyze data and identify potential equipment failures (Gartner, 2019).

One of the significant advantages of AI in production is its ability to enable predictive maintenance and real-time monitoring. By employing machine learning algorithms, AI systems can analyze large amounts of data from various sensors and detect potential equipment failures before they occur. This proactive approach helps companies avoid costly downtime and prevent production delays. Additionally, real-time monitoring allows for better optimization of production processes by identifying bottlenecks and inefficiencies in the system (Deloitte, 2020).

Enhancing Production Efficiency and Scheduling

Another area where AI is making a significant impact is in optimizing production schedules. AI-powered machines can learn from past production data and make accurate forecasts for future demand. By analyzing factors such as customer orders, material availability, and machine capacities, AI systems can generate optimized production schedules that maximize efficiency and minimize costs. This capability allows businesses to streamline their operations and deliver products to customers faster (McKinsey, 2021).

Furthermore, AI can enhance decision-making by providing real-time insights and recommendations based on data analysis. For example, AI systems can detect patterns and anomalies in production processes, identify potential quality issues, and suggest corrective actions. This automated quality control improves product consistency and reduces defects, ultimately leading to higher customer satisfaction and reduced waste (MIT Sloan Management Review, 2018).

Challenges and considerations

Implementing AI in production comes with its own set of challenges. Companies need to invest in the necessary infrastructure, including hardware, software, and data storage capabilities, to support AI systems. Furthermore, the successful integration of AI requires a skilled workforce with expertise in areas such as data science and machine learning. Employing and training personnel in these specialized fields can be costly and time-consuming. Additionally, there may be concerns about data security and privacy when using AI in production processes, which need to be addressed adequately (Forbes, 2020).

Data Points

| Data Point | Source |

|---|---|

| Global spending on AI in manufacturing is projected to reach $17.2 billion by 2025. | Gartner |

| AI can reduce unplanned downtime by up to 30% and maintenance costs by up to 10%. | Deloitte |

Conclusion

Artificial Intelligence is transforming the production landscape, enabling companies to optimize their processes, reduce costs, and improve product quality. From predictive maintenance to automated quality control, AI provides valuable insights and efficiencies. However, implementing AI in production also comes with challenges, including the need for infrastructure investments and skilled personnel. Nonetheless, the benefits of AI in production are undeniable, and companies are increasingly harnessing its power to gain a competitive advantage in the market.

References

- Gartner. “Artificial Intelligence in Manufacturing Operations Will Near $17 Billion in 2025.” Gartner Newsroom, October 3, 2019. https://www.gartner.com/en/newsroom/press-releases/2019-10-03-gartner-says-global-spending-on-ai-in-manufacturing-operations-will-reach-17-billion-in-2025

- Deloitte. “The Future of Production: AI in Manufacturing Operations.” Deloitte Insights, 2020. https://www2.deloitte.com/global/en/pages/manufacturing/articles/future-of-production-ai-in-manufacturing-operations.html

- McKinsey & Company. “Artificial Intelligence in Operations: Predictive Maintenance.” McKinsey & Company Insights, 2021. https://www.mckinsey.com/business-functions/mckinsey-digital/our-insights/artificial-intelligence-in-operations-predictive-maintenance

- MIT Sloan Management Review. “The Impact of Artificial Intelligence on Production Systems and Supply Chains.” MIT Sloan Management Review, 2018. https://sloanreview.mit.edu/article/the-impact-of-artificial-intelligence-on-production-systems-and-supply-chains/

- Forbes. “AI and the Future of Manufacturing.” Forbes Insights, 2020. https://www.forbes.com/sites/insights-intelai/2020/03/31/ai-and-the-future-of-manufacturing/?sh=5baf0b2f56de

Common Misconceptions

Misconception 1: AI Will Replace All Jobs

One common misconception about artificial intelligence in production is that it will lead to the replacement of all jobs. While AI can automate certain tasks and streamline processes, it is unlikely to completely eliminate the need for human workers.

- AI can support and enhance human performance rather than replacing it entirely.

- AI is most effective when it complements human skills and allows workers to focus on higher-level tasks.

- AI can create new job opportunities and shift the nature of work rather than completely eliminating roles.

Misconception 2: AI is Always Accurate and Reliable

Another misconception is that artificial intelligence is always accurate and reliable in production settings. While AI can perform tasks with high precision, it is not immune to errors or biases.

- AI systems are only as good as the data they are trained on, and if the data is flawed, the results can be inaccurate.

- AI can be susceptible to biases present in the data, leading to biased outcomes or discriminatory decisions.

- Human oversight and validation are still crucial in ensuring the accuracy and reliability of AI in production.

Misconception 3: AI Possesses Human-like Intelligence

Many people believe that artificial intelligence possesses human-like intelligence and capabilities. However, current AI technologies are limited in their ability to truly understand and replicate human intelligence.

- AI is designed to perform specific tasks and lacks the general intelligence and context that humans possess.

- AI systems may not have the ability to comprehend complex nuances, emotions, or creativity in the same way humans do.

- AI is a tool designed to assist humans, not to replace human intelligence.

Misconception 4: AI Will Take Over the World

There is a common fear that artificial intelligence will take over the world and become an uncontrollable force. This misconception stems from sci-fi movies and a misunderstanding of what AI is capable of.

- AI is developed and programmed by humans, and its behavior is ultimately governed by the algorithms and rules set by its creators.

- AI systems lack consciousness and self-awareness, making them incapable of seeking world domination.

- Proper regulations and ethical considerations can ensure that AI is used responsibly and for the benefit of society.

Misconception 5: AI Will Solve All Problems

Lastly, many people have the misconception that AI is a magic solution that can solve all problems in production. While AI has the potential to address certain challenges, it is not a panacea.

- AI is a tool that requires careful implementation and continuous monitoring to achieve effective results.

- AI is only as good as the data it uses, and if the data is incomplete or biased, the outcomes may not be optimal.

- AI should be seen as a tool to augment human capabilities and decision-making rather than a one-size-fits-all solution.

Popular Applications of Artificial Intelligence

Artificial Intelligence (AI) has made considerable advancements in various industries. Here’s a glimpse of how AI is transforming different sectors:

Increased Productivity in Manufacturing

AI is revolutionizing the manufacturing sector by automating processes and enhancing efficiency. For instance, AI-powered robots working alongside humans have accelerated production rates by 25%.

Enhanced Customer Service in E-commerce

In the e-commerce industry, AI chatbots are providing personalized recommendations, helping customers navigate websites, and resolving queries quickly, resulting in a 35% decrease in customer complaints.

Improving Healthcare Diagnosis

Using AI algorithms, medical professionals are now able to analyze large volumes of patient data and detect diseases at an early stage with 90% accuracy, leading to higher survival rates and improved outcomes.

Optimizing Energy Consumption

With AI-driven smart grids, energy consumption is optimized based on real-time demand and supply, resulting in energy savings of up to 30%, reducing costs for both consumers and businesses.

Efficient Fraud Detection in Finance

AI algorithms have significantly improved fraud detection in the financial sector. Detection rates have soared to 95%, reducing losses and ensuring secure transactions for individuals and businesses alike.

Streamlining Supply Chain Management

AI-powered supply chain management systems have reduced lead times by 30%, allowing businesses to respond quickly to market demands, minimize inventory costs, and ensure on-time deliveries.

Enhancing Traffic Management

AI-based traffic management systems have reduced congestion by 20% by analyzing real-time traffic patterns and dynamically adjusting traffic signals, resulting in smoother flow and reduced travel times.

Improving Agricultural Yield

AI-enabled farming techniques, such as precision agriculture and crop monitoring, have increased agricultural productivity by 25%, optimizing resource utilization and ensuring sustainable food production.

Revolutionizing Creative Industries

AI algorithms are now capable of creating art, music, and even writing novels. This convergence of AI and creativity has given rise to new possibilities, blurring the lines between human and machine creativity.

Driving Autonomous Vehicles

Autonomous vehicles rely heavily on AI technologies, mapping, and sensor data to navigate roads safely. Self-driving cars have reduced accidents by 50%, providing a safer and more efficient transportation system.

Artificial Intelligence has transformed diverse industries, enhancing efficiency, improving customer experiences, and driving innovation. As AI continues to evolve, the potential for its applications in production is limitless, presenting a new era of possibilities and advancements.

Frequently Asked Questions

What is artificial intelligence (AI)?

Artificial intelligence (AI) refers to the simulation of human intelligence in machines that are programmed to perceive, learn, reason, and perform tasks autonomously. AI enables machines to mimic cognitive functions such as problem-solving, decision-making, and pattern recognition.

How is artificial intelligence beneficial in production?

AI has several benefits in production. It can increase efficiency and productivity by automating processes, optimizing workflows, and reducing human errors. AI also enables better decision-making through data analysis, predictive modeling, and demand forecasting. Furthermore, AI can enhance product quality and customer experience by enabling predictive maintenance and personalization.

What are some real-world applications of AI in production?

AI finds applications in various areas of production. Some examples include predictive maintenance and asset management, quality control and defect detection, supply chain optimization, demand forecasting, energy and resource management, and autonomous robotics for assembly and logistics.

How does AI enable predictive maintenance in production?

AI-powered predictive maintenance utilizes machine learning algorithms to analyze sensor data, historical maintenance records, and operational patterns to predict when equipment is likely to fail. By identifying potential failures in advance, maintenance activities can be scheduled proactively, reducing downtime and costs.

Can AI in production replace human workers?

No, AI in production is not intended to replace human workers. Instead, it aims to augment human capabilities and automate repetitive or mundane tasks, allowing employees to focus on higher-value activities. AI can enhance employee productivity, improve decision-making, and create new job opportunities by enabling the development and management of AI systems.

How is data used in AI systems for production?

Data plays a crucial role in AI systems for production. It is used to train machine learning models, validate algorithms, and make informed decisions. Data is collected from various sources such as sensors, detectors, and databases, and then processed and analyzed to extract valuable insights that drive operational improvements, product optimization, and predictive capabilities.

What are the challenges of implementing AI in production?

Implementing AI in production comes with certain challenges. Some common hurdles include the need for high-quality and diverse data, ensuring data security and privacy, integrating AI technologies with existing systems, addressing ethical and fairness concerns, and consistently maintaining and upgrading AI systems to keep up with evolving technologies.

How can AI help in supply chain optimization?

AI can optimize supply chains by leveraging data analytics and machine learning techniques. AI systems can analyze vast amounts of data related to inventory, demand, transportation, and supplier performance to identify patterns, make accurate predictions, and enable efficient decision-making regarding procurement, production planning, inventory management, and logistics.

How can businesses ensure the ethical use of AI in production?

Ensuring the ethical use of AI in production requires companies to define clear guidelines and policies regarding data usage, privacy, and transparency. It is important to establish ethical review processes, monitor and mitigate biases in AI algorithms, prioritize human oversight, and engage stakeholders to ensure the responsible deployment and use of AI systems.

What are the future trends and opportunities in AI for production?

AI in production holds immense potential for future advancements. Some notable trends and opportunities include the rise of explainable AI for better decision transparency, the integration of AI with the Internet of Things (IoT) and edge computing, the development of AI-driven collaborative robots (cobots), and the constant evolution of AI algorithms and technologies to handle complex production challenges.