Artificial Intelligence in Production and Operations Management

Artificial Intelligence (AI) has revolutionized various industries, and production and operations management is no exception. AI technologies such as machine learning, data analytics, and robotics have transformed the way businesses manage and optimize their production processes. By leveraging AI, companies can improve efficiency, reduce costs, and enhance decision-making.

Key Takeaways

- AI technologies like machine learning and data analytics are transforming production and operations management.

- AI improves efficiency, reduces costs, and enhances decision-making in production processes.

- Collaboration between AI systems and human operators can lead to better outcomes.

- Security and ethical considerations are crucial when implementing AI in production and operations management.

The Role of AI in Production and Operations Management

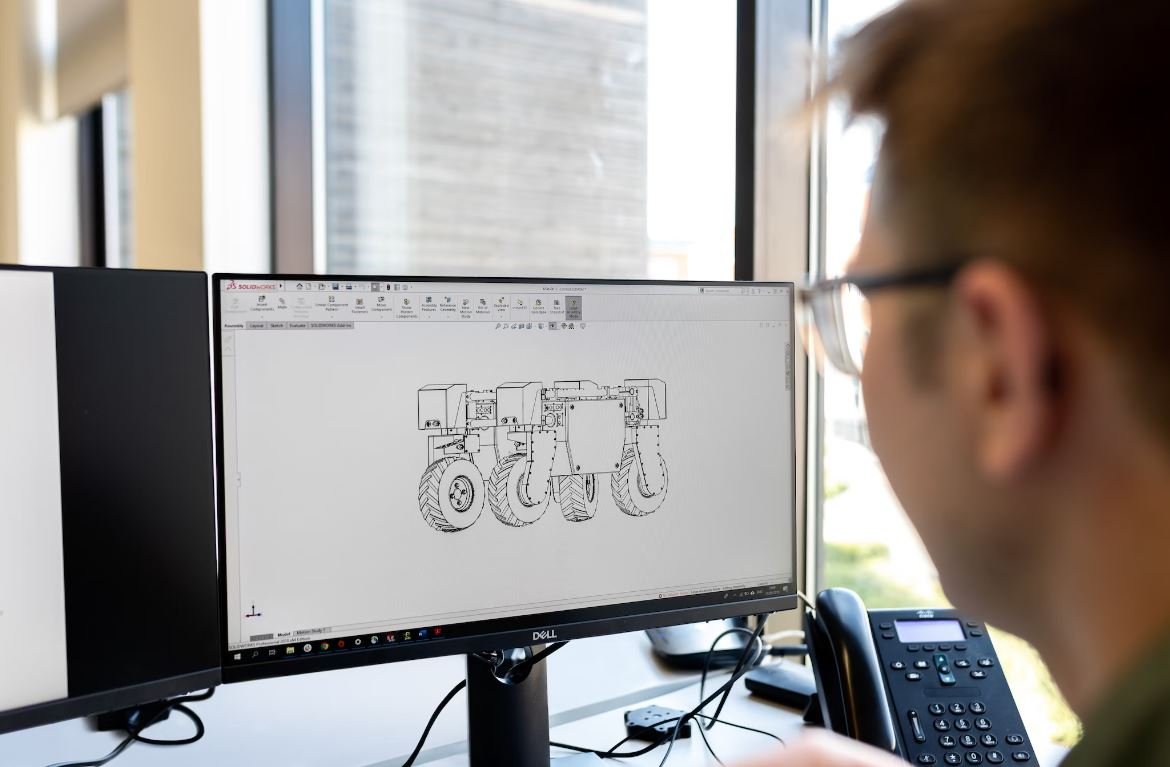

AI plays a significant role in optimizing production and operations management by analyzing large volumes of data and identifying patterns and insights. Machine learning algorithms can analyze historical production data to identify optimal process parameters, leading to improved product quality and reduced waste. *AI also enables predictive maintenance, allowing organizations to proactively address equipment issues before they lead to costly breakdowns and downtime.*

Applications of AI in Production and Operations Management

AI finds applications across various aspects of production and operations management. One key area is demand forecasting, where AI algorithms analyze historical sales data and external factors like weather and market trends to predict future demand accurately. Another crucial application is supply chain optimization, where AI algorithms optimize inventory management, route planning, and supplier selection to streamline operations and reduce costs.

Tables: Example Data Points

| Example 1 | Example 2 |

|---|---|

| Data Point 1 | Data Point 1 |

| Data Point 2 | Data Point 2 |

AI and Human Collaboration

While AI can automate various tasks in production and operations management, successful implementation often requires collaboration between AI systems and human operators. Humans possess contextual knowledge and intuition, which complement the analytical capabilities of AI systems. Together, they can make better decisions and address complex production challenges. *AI can assist operators in real-time decision-making by providing actionable insights based on data analysis and predictions.*

Considerations for Implementing AI in Production and Operations Management

- Ensure data quality and availability for effective AI implementation.

- Address security concerns related to AI systems accessing sensitive production data.

- Reskill and upskill the workforce to adapt and collaborate with AI technologies.

- Make ethical considerations to ensure AI systems are used responsibly and do not compromise human safety or well-being.

Table: Example Comparison

| Category | AI Implementation | Traditional Approach |

|---|---|---|

| Efficiency | Higher efficiency through automation and optimization. | Tendency for manual processes and potential inefficiencies. |

| Cost | Potential cost savings through improved resource utilization. | Higher costs due to human error and suboptimal processes. |

| Decision-making | Data-driven insights for better decision-making. | Reliance on experience and intuition, increasing the risk of biases. |

The Future of AI in Production and Operations Management

AI is continuously evolving, and its impact on production and operations management is likely to grow further. Advancements in robotics and automation will lead to increased adoption of AI-driven systems that can handle complex tasks with minimal human intervention. Furthermore, integrating AI with Internet of Things (IoT) technologies will enable the seamless sharing of real-time data across the production network. This integration will facilitate agile decision-making and optimization, making production and operations management even more efficient and responsive.

AI brings Efficiency, Cost Savings, and Improvement in Decision-Making

With the ability to analyze vast amounts of data, identify patterns, and optimize processes, AI is transforming production and operations management. It brings efficiency improvements, cost savings, and better decision-making capabilities to businesses across various industries. Embracing AI technologies in production and operations management enables organizations to stay competitive in today’s dynamic and data-driven business environment.

Common Misconceptions

There are several common misconceptions surrounding the use of Artificial Intelligence (AI) in Production and Operations Management. These misconceptions often stem from a lack of understanding about the capabilities and limitations of AI in this field. It is important to address these misconceptions in order to have a more accurate understanding of the role of AI in production and operations management.

Misconception 1: AI will replace human workers

- AI can automate routine and repetitive tasks, but it cannot replace humans in complex decision-making or tasks that require creativity and empathy.

- AI is designed to augment human capabilities and improve productivity, not to completely replace human workers.

- While AI can streamline operations and reduce the need for certain manual tasks, it often creates new job opportunities that require human involvement.

Misconception 2: AI solutions are always accurate and reliable

- AI algorithms are highly dependent on the data they are trained on. If the data is biased or incomplete, AI solutions can also produce biased or inaccurate results.

- AI models can be vulnerable to adversarial attacks, where malicious actors intentionally manipulate the data to deceive the AI system.

- AI solutions need to be continuously monitored and updated to ensure their accuracy and reliability over time. They are not infallible and require human intervention.

Misconception 3: AI implementation is expensive and complex

- While AI implementation can require investment, it does not always have to be expensive. There are open-source AI frameworks and tools available that can significantly reduce the cost of implementation.

- A successful AI implementation requires a clear strategy, proper planning, and collaboration between different stakeholders, but it does not necessarily have to be overly complex.

- Organizations can start small by implementing AI in specific areas of production and operations management, gradually expanding its usage as they gain experience and knowledge.

Misconception 4: AI will make all decisions autonomously

- AI systems are not meant to make all decisions autonomously without human involvement. They are designed to assist and support human decision-making processes.

- Human oversight and intervention are crucial to ensure that AI makes ethical and responsible decisions, especially in sensitive areas such as safety and regulatory compliance.

- AI can provide recommendations and insights based on large amounts of data, but the final decision-making authority remains with humans.

Misconception 5: AI implementation will lead to job losses

- While AI may automate certain tasks, it can also create new job roles and opportunities.

- AI implementation can free up human workers from mundane tasks and allow them to focus on more complex and value-added activities.

- AI can enhance workforce productivity, leading to overall growth and expansion of businesses, which in turn can create more job opportunities.

The Impact of Artificial Intelligence in Supply Chain Management

In recent years, the integration of artificial intelligence (AI) in supply chain management has revolutionized the way businesses operate. AI-powered technologies have enabled companies to enhance efficiency, reduce costs, and improve customer satisfaction. The following table highlights key statistics about the impact of AI in supply chain management:

Applications of Artificial Intelligence in Production Planning

The utilization of artificial intelligence (AI) in production planning has significantly transformed the manufacturing industry. AI algorithms have the capacity to optimize production schedules, reduce lead times, and enhance resource allocation. The table below showcases some notable applications of AI in production planning:

The Role of Artificial Intelligence in Quality Control

Artificial intelligence (AI) has emerged as a game-changer in the field of quality control. Through AI-powered systems, manufacturers can automate inspections, detect defects with precision, and ensure consistent product quality. The table provided below presents key information about the role of AI in quality control:

Artificial Intelligence for Inventory Management Optimization

Optimizing inventory management is crucial for businesses to minimize costs, prevent stockouts, and meet customer demands effectively. With the integration of artificial intelligence (AI), companies can analyze complex data sets, forecast demand, and make data-driven inventory decisions. The table below demonstrates the impact of AI in inventory management optimization:

Artificial Intelligence in Predictive Maintenance for Machinery

Predictive maintenance using artificial intelligence (AI) has revolutionized the management of machinery and equipment. By analyzing sensor data and machine learning algorithms, AI systems can predict maintenance needs, prevent unexpected breakdowns, and optimize maintenance schedules. The table presented below highlights the advantages of AI in predictive maintenance for machinery:

Artificial Intelligence-Based Risk Management in Operations

Risk management is a critical aspect of operations. Artificial intelligence (AI) enables businesses to analyze vast amounts of data, identify potential risks, and develop proactive mitigation strategies. The table below outlines some key applications of AI-based risk management in operations:

Artificial Intelligence-Driven Demand Forecasting

Accurate demand forecasting is crucial for businesses to optimize production plans, reduce inventory costs, and meet customer demands. Artificial intelligence (AI)-driven forecasting models can process large volumes of data, consider multiple variables, and provide highly accurate predictions. The table below presents important statistics related to AI-driven demand forecasting:

Artificial Intelligence for Optimizing Manufacturing Processes

Artificial intelligence (AI) has proven to be invaluable in optimizing manufacturing processes, streamlining operations, and improving overall efficiency. By analyzing data in real-time, AI systems can identify bottlenecks, reduce cycle times, and enhance productivity. The table below highlights the impact of AI in optimizing manufacturing processes:

Artificial Intelligence-Based Energy Management in Operations

Effective energy management is becoming increasingly important in the operational practices of businesses. Artificial intelligence (AI) can analyze energy consumption patterns, optimize energy usage, and identify potential areas for energy savings. The table provided below showcases the benefits of AI-based energy management in operations:

Artificial Intelligence in Supply Chain Risk Assessment

Supply chain risk assessment is a critical component of operations management. By incorporating artificial intelligence (AI), businesses can identify potential risks, develop contingency plans, and mitigate disruptions effectively. The table below presents some key insights into the use of AI in supply chain risk assessment:

As technology continues to evolve, the integration of artificial intelligence (AI) is increasingly reshaping production and operations management. From optimizing supply chains to enhancing quality control, AI offers numerous advantages across various aspects of the manufacturing industry. By leveraging the power of AI, businesses can boost efficiency, reduce costs, and stay competitive in an ever-changing market landscape.

Frequently Asked Questions

What is Artificial Intelligence (AI) in the Context of Production and Operations Management (POM)?

How Can AI be Applied in Production and Operations Management?

What are the Benefits of Using AI in Production and Operations Management?

Are There Any Challenges Associated with Implementing AI in Production and Operations Management?

What are Some Use Cases of AI in Production and Operations Management?

How Does AI-Powered Predictive Maintenance Work in Production and Operations Management?

Can AI Enhance Supply Chain Management in Production and Operations Management?

What are the Implications of AI on Workforce in Production and Operations Management?

How Can AI be Used for Quality Control in Production and Operations Management?

What is the Role of AI in Improving Customer Service in Production and Operations Management?