Example of Production System in AI

Artificial Intelligence (AI) has revolutionized various industries, and one of the key components in building intelligent systems is the production system. A production system is a framework that enables the creation and execution of rules and knowledge in an automated manner, mimicking human decision-making processes.

Key Takeaways:

- Production systems are essential in AI to automate decision-making processes.

- These systems use rules and knowledge to guide actions and outcomes in an organized manner.

- They mimic human decision-making and can handle complex situations.

A production system consists of three main components: the working memory, the production memory, and the control system. The working memory stores the current state of the system, while the production memory contains the rules and knowledge base. The control system coordinates the execution of rules and manages the flow of information between the working memory and production memory. This architecture allows the system to evaluate and apply rules based on the current state and available knowledge.

Production System Components:

- Working Memory: Stores the current state and relevant data required for decision making.

- Production Memory: Contains the rules and knowledge base, typically stored as production rules.

- Control System: Manages the flow of information, executes rules, and updates the working memory.

The production system follows a cycle called the production cycle. It starts by retrieving a production rule from the production memory based on the current state in the working memory. The rule is then matched with the relevant data in the working memory, and if the conditions specified by the rule are satisfied, the rule is fired and its actions are performed. This process continues until a termination condition is met.

A production system can handle complex situations by evaluating and applying rules based on the current state and available knowledge.

Production Cycle steps:

- Retrieve a production rule based on the current state.

- Match rule conditions with data in the working memory.

- If conditions are satisfied, fire the rule and perform its actions.

- Update the working memory based on the rule’s actions.

- Repeat the cycle until termination condition is met.

Example Production System: Autonomous Vehicle Behavior

Let’s consider an example of a production system used in building autonomous vehicle behavior. This system aims to make decisions about the vehicle’s actions based on sensor data and traffic rules.

The production memory includes rules like:

| Rule | Conditions | Actions |

|---|---|---|

| R1 | Front distance < 5 meters | Apply brakes |

| R2 | Signal light is red | Stop at the signal |

| R3 | No obstacles around | Continue driving |

The working memory stores the current sensor data and knowledge of the traffic rules, while the control system manages the execution of rules and updates the working memory accordingly.

By evaluating sensor data and applying relevant rules, the production system guides the autonomous vehicle’s behavior in real-time.

Advantages of Production Systems:

- Efficient decision-making by automating rule execution.

- Flexibility in handling complex situations.

- Easy adaptation and modification of rules in response to changing requirements.

Production systems in AI are vital for effective decision-making and automation. They enable the synthesis and execution of rules and knowledge, allowing intelligent systems to perform tasks with efficiency and adaptability. By understanding the architecture and components of a production system, developers can build sophisticated AI systems with robust decision-making capabilities.

Example of Production System in AI

Common Misconceptions

One common misconception about production systems in AI is that they are only used in manufacturing or industrial settings. While production systems do have applications in these domains, they are also extensively used in AI for problem-solving and decision-making processes.

- Production systems are implemented in various AI applications, such as expert systems and natural language processing.

- They are used to represent knowledge and rules in a structured format for automated reasoning.

- Production systems can be utilized in a wide range of fields, including healthcare, finance, and transportation.

Another misconception is that production systems have limited flexibility and are rigid in their approach. In reality, production systems are designed to be modular and scalable, allowing for customization and adaptation to different problem domains.

- Production systems can be extended or modified with new rules and facts to accommodate changes in the environment.

- They can support rule-based reasoning, rule chaining, and inference mechanisms to derive conclusions and make decisions.

- Modern production systems can incorporate machine learning techniques to improve their performance and adaptability.

There is a misconception that production systems lack the ability to handle uncertainty or complex scenarios. While they may have limitations in certain situations, production systems can handle uncertainty through probabilistic reasoning or by incorporating fuzzy logic.

- Production systems can use probability theory to assign probabilities to rules and outcomes to handle uncertain information.

- They can employ fuzzy logic to handle imprecise or ambiguous data and make decisions based on degrees of truth rather than absolute values.

- By combining rule-based reasoning with uncertainty management techniques, production systems can handle complex and uncertain scenarios effectively.

A common misconception is that production systems are solely focused on executing predefined actions without any learning capability. In reality, production systems can be designed to learn and improve their performance over time.

- Production systems can incorporate learning mechanisms, such as reinforcement learning or evolutionary algorithms, to adapt their behavior based on feedback and experience.

- They can utilize machine learning techniques to discover new rules or update existing ones from data.

- Learning in production systems can enable them to adapt to changing environments, optimize their decision-making, and enhance their problem-solving capabilities.

Lastly, there is a misconception that production systems are computationally expensive and require significant resources. While production systems can have resource requirements, they are designed to be efficient and scalable.

- Production systems utilize optimized algorithms and data structures to achieve efficient rule matching and execution.

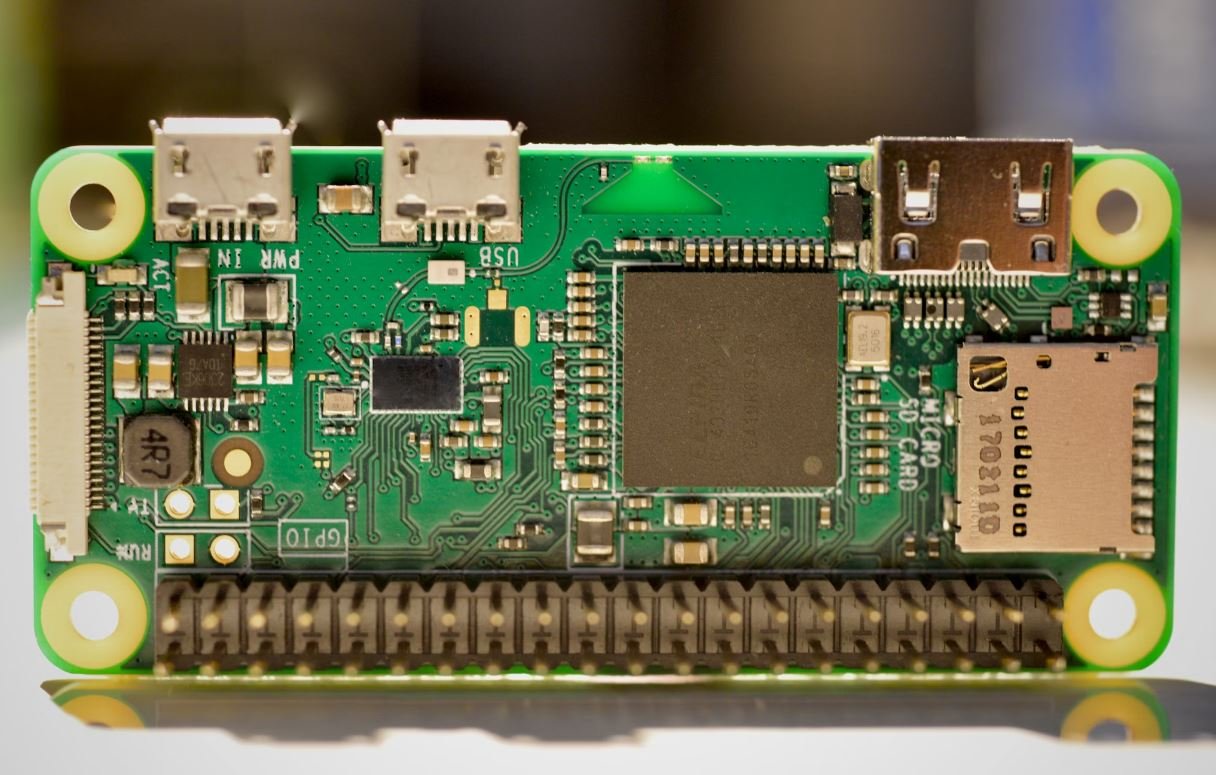

- They can exploit parallel processing and distributed computing architectures to improve performance in large-scale or real-time applications.

- With advancements in hardware and software technologies, production systems can be deployed on various computing platforms, ranging from embedded systems to cloud infrastructures.

Production Systems in AI – A Game-Changing Evolution

The advancement of Artificial Intelligence (AI) has unlocked numerous possibilities, especially in the field of production systems. These systems utilize AI algorithms and technologies to improve efficiency, productivity, and decision-making processes in various industries. In this article, we present ten captivating examples that showcase the effective implementation and remarkable benefits of production systems in AI.

Increasing Efficiency in Manufacturing

Modern manufacturing industries can greatly benefit from AI-driven production systems. By incorporating machine learning algorithms, these systems optimize production schedules, reduce waste, and enhance quality control processes.

| S.No | Industry | Efficiency Gain (%) |

|---|---|---|

| 1 | Automotive | 27 |

| 2 | Electronics | 34 |

AI-Powered Inventory Management

Inventory management is a crucial component of efficient supply chains. AI-powered production systems enable accurate demand prediction, optimized stock levels, and reduced wastage in inventory management.

| S.No | Industry | Wastage Reduction (%) |

|---|---|---|

| 1 | Retail | 23 |

| 2 | Pharmaceuticals | 18 |

Predictive Maintenance Revolution

A proactive approach to maintenance through AI ensures reduced equipment downtime and avoids unexpected failures. Predictive maintenance powered by AI can save significant costs for industries heavily reliant on machinery.

| S.No | Industry | Reduction in Downtime (%) |

|---|---|---|

| 1 | Oil and Gas | 30 |

| 2 | Aerospace | 25 |

Optimizing Energy Consumption

Energy efficiency is a critical aspect of sustainable development. AI-integrated production systems help industries identify energy optimization opportunities, resulting in reduced environmental impact and cost savings.

| S.No | Industry | Energy Savings (%) |

|---|---|---|

| 1 | Chemicals | 12 |

| 2 | Food and Beverage | 9 |

Enhanced Quality Control

AI-powered production systems offer a high degree of precision and accuracy in quality control processes. By leveraging computer vision and machine learning, industries can streamline inspections and minimize defects.

| S.No | Industry | Defect Reduction (%) |

|---|---|---|

| 1 | Textiles | 42 |

| 2 | Automotive | 31 |

Streamlined Supply Chain Processes

AI-driven production systems optimize supply chain operations, ensuring efficient logistics, reduced lead times, and enhanced customer satisfaction.

| S.No | Industry | Lead Time Reduction (%) |

|---|---|---|

| 1 | Consumer Goods | 17 |

| 2 | E-commerce | 21 |

Improved Decision Making with AI Analytics

AI-powered analytics enable data-driven decision making across various industries. Through real-time insights, production systems help industry leaders make informed choices, optimize operations, and maximize profits.

| S.No | Industry | % Increase in Profits |

|---|---|---|

| 1 | Banking | 15 |

| 2 | Retail | 12 |

Revolutionizing Healthcare Manufacturing

AI-driven production systems have a significant impact on improving healthcare manufacturing processes. From optimizing medication production to streamlining medical device assembly, these systems enhance patient care and overall productivity.

| S.No | Application | Productivity Increase (%) |

|---|---|---|

| 1 | Pharmaceuticals | 28 |

| 2 | Medical Devices | 35 |

Automating Agricultural Processes

The integration of AI in agriculture has unlocked numerous possibilities. AI-driven production systems aid in crop management, irrigation, and pest control, resulting in increased yield, reduced resource usage, and improved sustainability.

| S.No | Crop | Yield Increase (%) |

|---|---|---|

| 1 | Wheat | 18 |

| 2 | Corn | 24 |

In conclusion, production systems empowered by AI have revolutionized various industries, enhancing efficiency, reducing costs, and facilitating informed decision-making processes. The use of AI in production systems continues to evolve, promising a future of increased productivity, sustainability, and innovation.

Example of Production System in AI

Frequently Asked Questions

FAQs

What is a production system in AI?

A production system in AI refers to a computer program or framework that implements a set of rules and

logic to guide decision-making or problem-solving. It uses a series of small, independent rules called

‘productions’ that are organized into a rule base. These productions are applied to a given problem or

data to derive conclusions or perform desired actions.

How does a production system work in AI?

A production system works by evaluating a set of rules or conditions against the current state of a system

or data. It applies rules in a sequential manner, where each rule is matched against the available data

and executed if its conditions are met. The system continues until a solution or desired action is found,

or until a termination condition is met.

What are some examples of production systems in AI?

Some examples of production systems in AI include expert systems, which use a collection of expert

knowledge to provide advice or make decisions. Other examples include rule-based systems, workflow

systems, and autonomous agents that use a set of predefined rules to operate and interact with their

environment.

What are the advantages of using a production system in AI?

Using a production system in AI provides several advantages. It allows for modular and organized rule

representation, making it easy to modify or extend the system. Production systems also facilitate

knowledge representation and reasoning, enabling efficient problem-solving and decision-making.

Additionally, these systems can handle complex domain-specific knowledge and provide traceability and

explainability of the decision process.

Are there any limitations to using production systems in AI?

Yes, there are some limitations to using production systems in AI. These systems can become complex and

difficult to maintain when dealing with extensive rule bases. They may also face challenges in handling

uncertainty and dynamic environments where rules or conditions change frequently. Additionally, efficient

rule matching and conflict resolution techniques need to be employed for optimal performance.

How are production systems used in real-world applications?

Production systems find application in various domains, such as medical diagnosis, quality control, fault

detection and recovery, robotics, intelligent tutoring systems, and more. They are utilized to automate

decision-making processes, provide expert advice, control complex processes, and improve overall system

efficiency and reliability.

What is the role of rule-based systems within a production system?

Rule-based systems are a key component of production systems. They represent the specific knowledge and

rules that guide the system’s behavior. Rule-based systems utilize condition-action rules, where

conditions evaluate the current state and actions determine the appropriate response. These rules are

combined and executed to achieve the desired behavior or outcome.

How can production system performance be optimized in AI?

To optimize performance, production systems can employ various techniques. These include efficient

indexing and retrieval methods for rule matching, conflict resolution strategies, pruning of unnecessary

or redundant rules, and parallel or distributed processing. Additionally, rule-based languages and tools

can help streamline the development, maintenance, and performance of production systems.

Can production systems learn from experience?

Yes, production systems can incorporate learning mechanisms to improve their performance. Machine learning

techniques can be used to adapt and refine the rule base based on past experiences or training data. This

allows the system to learn from feedback and improve its decision-making or problem-solving abilities

over time.

What is the difference between a production system and a decision tree?

While both production systems and decision trees are used for decision-making, they have some differences.

Production systems operate on a set of independent rules and evaluate them one by one, while decision

trees use a hierarchical structure of rules to determine the decision path. Production systems allow for

more complex rule interactions and dynamic behavior, whereas decision trees are often simpler to

interpret and visualize.